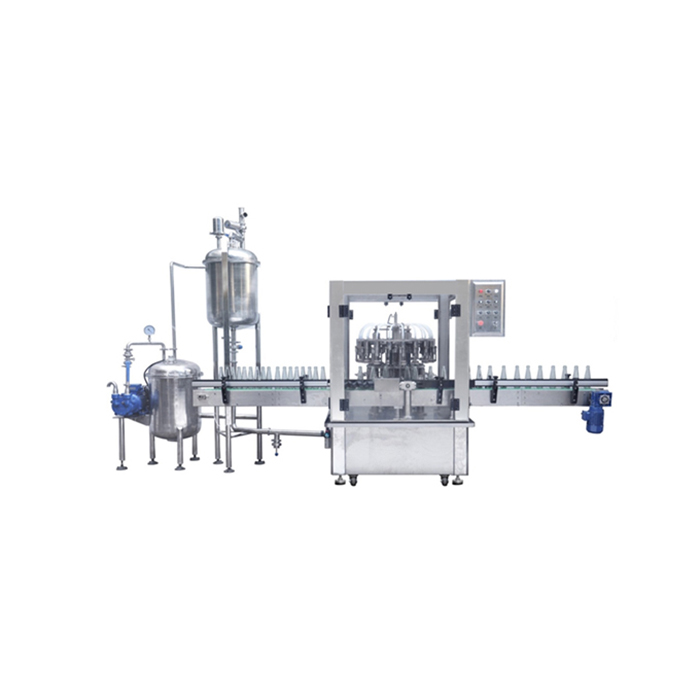

Monoblock Filling Machine

A monoblock filling machine is a type of packaging machinery used for filling liquids and other viscous products into containers. The monoblock filling machine typically performs three operations – filling, capping, and labeling – in a single unit, making it an efficient and cost-effective solution for high-speed production lines.

The machine is composed of two or more stations mounted on a single frame, with each station handling a different task in the filling process. These stations typically include a filling station, a capping station, and a labeling station. Each station is synchronized with the others to ensure a smooth, uninterrupted filling process.

The filling station of the monoblock filling machine uses a volumetric, gravity, or piston filling method to accurately measure and dispense the liquid into the container. The capping station uses various capping technologies to tightly seal the container with a cap or closure. The labeling station applies labels to the containers to identify the product and convey important information such as expiration dates, product codes, and barcodes.

Monoblock filling machines are designed to handle a wide range of container sizes and shapes, from small vials to large bottles, and can accommodate a variety of liquid and viscous products, including oils, juices, sauces, and pharmaceuticals.

The benefits of using a monoblock filling machine include increased production rates, reduced labor costs, improved accuracy and consistency, and reduced risk of contamination or spills. The compact design of the machine also makes it ideal for use in small spaces or where floor space is at a premium.

In conclusion, a monoblock filling machine is a versatile and efficient solution for high-speed liquid filling and packaging. Its multiple stations and synchronized operation make it a valuable addition to any production line, providing increased productivity, cost savings, and improved product quality.